The Original Mattress Factory Test Center

The Original Mattress Factory is committed to making quality products that are built right — and built to last. That’s why we’re always testing new products and conducting research on the latest technology at our own Test Center located in our Cleveland, OH factory. Three testing stations help us evaluate our current products, competitive products, new design ideas, and component materials.

We conduct all tests in accordance with ASTM International standards. Before and after conducting the Rollator and Cornell tests, we evaluate:

- Surface profile of the mattress

- Product appearance and condition

- Firmness

Then, we evaluate each internal component of the mattress through a thorough teardown inspection.

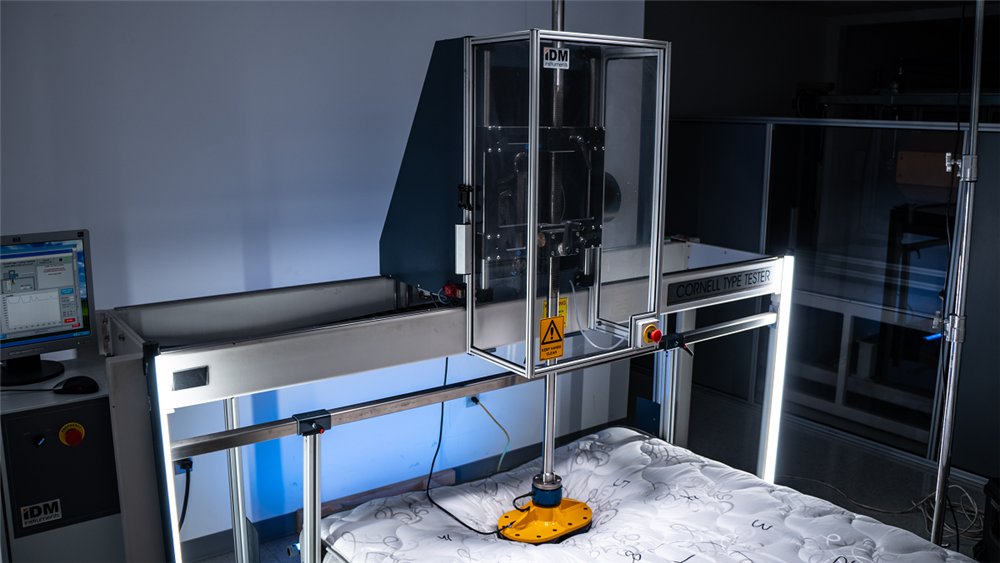

CORNELL TESTER (AKA THE IMPACT TEST)

The Cornell Tester is designed to simulate a person sitting in the same spot on a mattress set.

- A dual-sphere shaped ram-head applies a 230-pound load to a set position.

- The test, which runs for approximately 11 hours, consists of 100,000 cycles at a speed of 160 strokes per minute.

- A complete test simulates 10 years of use.

- Height and firmness measurements are taken at multiple intervals during the test.

MATTRESS ROLLATOR (AKA THE TOSS AND TURN TEST)

The Rollator is designed to simulate a person rolling back and forth across the mattress.

- A 240-pound, hexagonal-shaped roller passes back and forth across the width of the mattress set 200,000 times.

- The test runs nonstop for nearly four days.

- A complete test simulates 10 years of use.

- Upon completion, the surface condition and profile of the mattress set are evaluated and compared to results collected before the test. Additional measurements are taken after a 24-hour recovery period to determine any changes.

FOAM COMPRESSION TESTER (AKA THE PRESSURE TEST)

The Foam Compression Tester is designed to evaluate the height and firmness of a mattress or mattress set.

- A 13.5-inch circular plate is used to measure indentation load deflection (ILD) between 0 inches and 4 inches in .5-inch increments.

- These measurements represent the firmness (or feel) of the product and are taken at five different locations on the mattress that are meant to represent different areas of the body (e.g. head, shoulder, calf and hip).