Buying a Mattress: Support

Proper support is vital to healthy sleep. Without it, you may struggle to get truly comfortable or wake up with aches and pains. Every mattress we offer at OMF can provide adequate adult-level support for every night use.

There is a common misconception that a mattress must be firm in order to be supportive. Support comes from the core of the mattress. The core can be an innerspring unit, foam, air, or water. When you have a high-quality core, you can add many layers of upholstery to create a very soft mattress and still maintain proper support. Learn more here.

How can you tell if a mattress has the support you need? Understand the materials used to build the core of the mattress and test it out for as long as possible. We always recommend testing it out for at least 15 minutes in your natural sleeping position. This will give your body an opportunity to settle into the mattress and sense not only the top upholstery layers but also the underlying support structure.

We’ll take a look at each core material and offer our advice for identifying goodsupport.

Innerspring support

Innersprings are the most common support system used in mattresses. But there are many types of innersprings available, so they vary widely in quality and support. In general, just remember that more steel means better support and durability.

There are a few elements to consider when you’re evaluating the support of an innerspring system:

1. Coil count

The number of coils in your mattress is not the best way to evaluate the quality of the support in a mattress. Keep in mind that it’s easy to cram in more coils if those coils are low quality. There should be a minimum of 300 coils in a full size, 375 in a queen, and 450 in a king, but this shouldn’t be the only factor you consider.

2. Gauge

Gauge is the thickness of the wire used for the coils. The lower the number, the thicker the wire. For example, a 12.75-gauge wire is actually thicker than a 15-gauge wire.

3. Turns or rotations

The more turns or rotations a coil has, the more durable that coil will be. More turns allow the sleeper’s weight to be distributed across more wire, resulting in less wire fatigue in the coil.

Coil turns

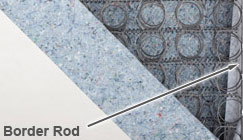

4. Edge-to-edge support

An innerspring unit can offer edge-to-edge support, or it can be foam encased (as is common with pocketed coil systems). Some innerspring units with edge-to-edge support (like those in OMF innerspring mattresses) also feature a border rod around the perimeter for additional edge support. A foam-encased unit is smaller in size because coils are removed and replaced with a foam edge.

Border Rod

Foam Encasement

5. Coil designs

There are six basic types of innerspring coil designs. Each of these can be classified as either open ended or knotted. Knotting the ends of the coil gives the coil more stability.

Coils can also go through a process called tempering. Tempered innersprings are stronger and more durable. The tempering process, which involves heating the wire or innerspring unit to a high temperature, can be done electrically or in a tempering oven. The term “double tempered” or “twice tempered” is often used in the industry, but once a coil has been heated to the optimum temperature to achieve tempering, it cannot be tempered twice. All coils used by The Original Mattress Factory are tempered for maximum durability.

- Bonnell: An hourglass-shaped coil with a round, knotted head. It is made with tempered steel and at one time was commonly used in most mainstream brands’ entry level products as well as some promotional products. The Bonnell coil has been largely replaced by the Veritcoil® in most mainstream mattress brands. The Bonnell coil unit is used in our Classic line.

- Continuous coil: A strip of coils that runs either vertically or horizontally with each head representing the end and beginning of consecutive coils. This design is made of one piece of tempered wire and commonly has a high coil count, but it uses less steel and a much thinner gauge of wire with a low number of turns.

- LFK coil: A straight-barrel coil with an offset, squared, and un-knotted head. It is made with tempered steel and is used in premium innerspring units. The LFK coil unit is used in our Regency line.

- Marshall or encased coil: A straight-barrel, un-knotted coil that is encased in fabric. It is sometimes made with non-tempered steel, which reduces the long-term resiliency of the springs. This is also known as an encased coil and is very common in mainstream mattress brands’ flagship lines.

Offset coil: An hourglass-shaped coil with a square head that is typically knotted. It is made of tempered steel and is used in premium-quality innerspring units found in high-end luxury brands. The square-head design works with neighboring coils to hinge, offering excellent body-conformance characteristics. Our best offset knotted coil unit is used in our Orthopedic line.

- Verticoil®: A fairly new design featuring a straight barrel coil with an open-ended, offset coil head design. It incorporates some of the attributes of an LFK coil design but in a size more similar to that of a Bonnell coil. The VertiCoil® unit typically utilizes thinner wire and fewer turns than other offerings and is now commonly used in most mainstream brand entry-level products.

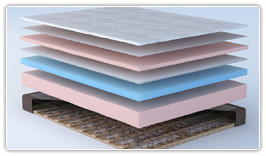

Foam support

All-foam mattresses will have a foam core — typically made of either polyurethane foam or latex foam. (Memory foam is also a common material used in mattresses, but it is not typically used for the core as it needs to be near the surface of the mattress in order to have any benefit to the sleeper. You can learn more about foam upholstery layers here.) Like an innerspring, the foam core conforms to your body while still providing high-quality support.

If you are interested in a mattress with a foam core, it is important to consider the type of foam as well as its density and indentation load deflection (ILD). Density is a measure of quality and is determined by weight per unit of volume, which is measured in pounds per cubic foot in foam. ILD is a measurement of a foam’s load-bearing capacity and is indicative of how hard or soft the foam feels.

Polyurethane foam

Polyurethane foam is a very common material used in the upholstery layers of a mattress, but it can also provide support as a core material when it is a high-density foam. When evaluating a mattress with a polyurethane foam core, we recommend looking for a core with a minimum density of 2 lb/ft3.

While lower-density foams are fine options for the upholstery layers, a dense foam core is required to provide firm support.

Latex foam

While less, some all-foam mattresses opt for a latex foam core. Latex foam can be made from natural latex, synthetic latex, or a blend of the two. Latex foam can also be made using one of two manufacturing processes: Talalay or Dunlop.

Density is also important for a latex foam core. We would recommend looking for a core with a minimum density of 3.5 lb/ft3. When density information isn’t available, we recommend a minimum ILD of 32.

Our Serenity Latex mattress has latex upholstery layers and utilizes a polyurethane core. We use latex foam from Talalay Global that is a blend of natural and synthetic latex to give the foam the right balance of comfort and durability. This foam is used in the Serenity Latex mattress as well as our latex foam pillows.

Air or water support

While waterbeds are not nearly as popular as they once were, air is still commonly used as a support core in mattresses. You won’t find either of these as options at OMF because they don’t provide active support. Air and water support your body through displacement. This can create a hammock-like effect when the air or water levels are lowered to soften the mattress.

How a box spring or foundation contributes to support

The box spring or foundation you pair with your mattress also plays a big role when it comes to support. If your mattress isn’t properly supported, it can negatively impact its performance. A real, flexing box spring acts as a shock absorber for your mattress and can improve its long-term comfort and durability. But the rigid foundations that are commonly found in mainstream mattress retailers don’t provide any shock-absorbing benefit to your mattress.

Visit an Original Mattress Factory location today

In order to best determine the quality of support a mattress offers, you have to know how it’s made. At The Original Mattress Factory, you can see and feel all of the materials we use to build our mattresses. All of our factories are open to the public, so you can see your mattress be built. We offer factory tours to individuals and groups.